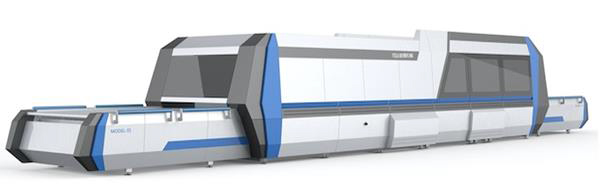

Brief introduction - The furnace includes loading table, heating section with forced convection system, quenching and cooling section, unloading table, and control system. It is used to manufacture flat tempered glass for furniture, home appliance, architecture glass, etc.

Loading Table - The loading table is composed of rubber-covered rollers and Kevlar rope. When the glass is put onto the rollers, the glass will be conveyed automatically to the entrance of the furnace where it will be in ready-to-enter-furnace position and the rollers slop moving. It will send the glass into the furnace once the computer control system gives enter command.

Heating Section - The structure of the heating section is of a double-layer box type covered with thermos-insulation material. Inside the sect on there is a conveyor system with high temperature resistant ceramic rollers. Heating elements and radiation plates are installed on the upper layer and lower layer or this section. The upper layer radiation plate is special heat resistant and anti-corrosion cast material. The heating element is of an integrated part with spiral type resistance erected on ceramic part, it's easy to replace. When the glass is going to enter the furnace, the front door of the heating section opens the rolls of the loading table and heating section move at the same time. When the glass is in the furnace, the front door will close and the glass on the rollers will be moved back and forth at the distance calculated by the controlling system automatically, so that the glass will be heated evenly. The upper sect on can be lifted up for maintenance. The heating elements are in matrix layout.

Flat Quenching/Cooling Section - The alloy sections and steel sheet is cold riveted to avoid deformation of heat welding, ensure effectively the entire flatness at air face of quench. Rational nozzle aperture and arrangement of air hole guarantee the glass even cooling. The upper and lower quenches are combined with linkage and individual drives, which can actually control the rational height for air nozzle or quenches. Matched with balance control of upper and lower air amount, the top and bottom of the glasses can reach to optimum heat radiation, so as to ensure the flatness of tempering glass.

Unloading Table - The unloading table is similar as the loading table. When the glass is transported to the the conveyor, the rollers will stop, and the glass can be taken away by hand, or by robot, if there Is available at the customer’s factory.

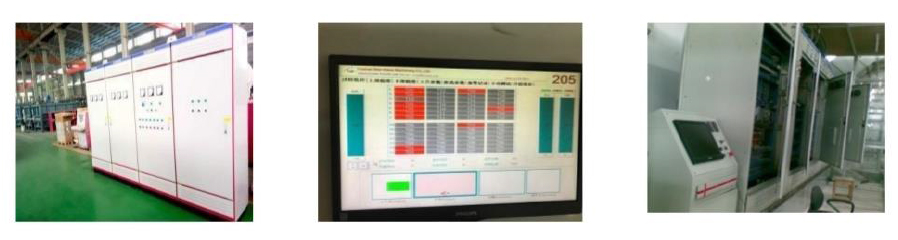

Control System

Technical Parts

Supply Scope

Loading table

Heating section (furnace) with top fan convection system

Quenching and Cooling section

Unloading table

Blower system

Control system

Convection system

| Model | STG-A2233 |

| Flat Glass size | Max loading area / 2200 x 3300mm |

| Glass thickness range / 5-19mm | |

| Max Glass size / 5-19mm : 2440 – 3660 mm | |

| Min Glass size / 300x400mm | |

| Recommended transformer capacity | ≥ 630KVA |

| Blower Control | 1 controlled by frequency inverters |

| Quality Standard | ANSI Z97.1-2004, |

| Finished product rate | ≥98% |

| Installation period (approximately) | 15 working days |

| Commissioning period (approximately) | 7 working days |

| Training period (approximately) | 1 working week |

| Guarantee period | ONE year for non worn-out parts and components. |

| Power supplier mode | 380 V + 50 HZ (Can order) |

| Glass | Glass tempered | Note |

| Thickness (mm) | cycle (load/hour) | |

| 4 | 36-40 | The size, producing area and color of glass panel will cause the production difference. The production of glass plate with small size and deep color will be slightly larger. |

| 5 | 16-18 | |

| 6 | 14-16 | |

| 8 | 10-12 | |

| 10 | 9-10 | |

| 12 | 7-8 | |

| 15 | 5-6 | |

| 19 | 3-4 |

Power Consumption : Flat <4kwh/m2

Productivity: 4mm glass 22 cycle/hour

Suitable glass sorts

Tinted glass

Patented glass

Silk screen printing glass

Clear float glass

Low-E glass

| No | Main part | Brand |

| 1 | Industry Computer | Advantech |

| 2 | Temperature Controller | STAR |

| 3 | PLC Input Board PLC | Siemens |

| 4 | Encoder | Koyo |

| 5 | Circuit Breaker | LG/MULLER |

| 6 | Photo Switch | Autonics |

| 7 | Proximity Switch | Autonics |

| 8 | SSR | YANGMING |

| 9 | Drive Inverter | Schneider Electric |

| 10 | Blower Inverter | Hekan |

| 11 | Relay | Weidmuller |

| 12 | Ups | KEHUA |

| 13 | Electromagnetic wave | Airtac of Taiwan |

| 14 | Cylinder | Airtac of Taiwan |

| 15 | Bearing | SKF for blower bearing Normal bearing for machine adept HRB |

| 16 | HI-AL thermal resistant board(inside) | LUYANG |

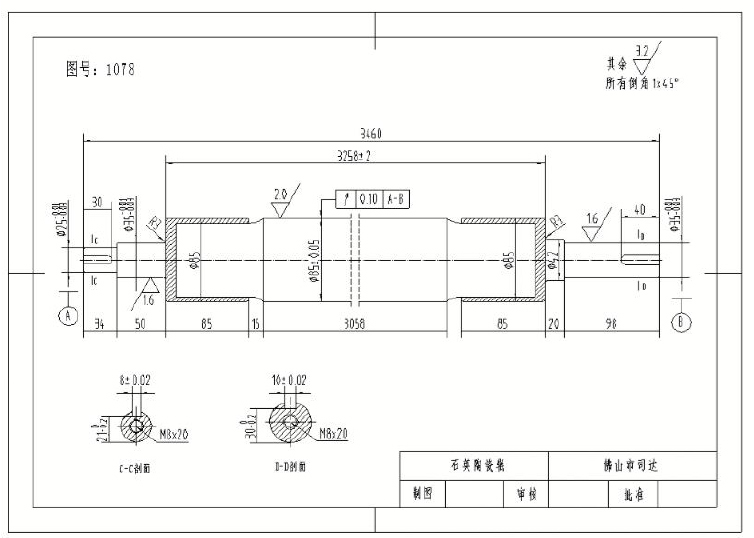

| 17 | Ceramic roller 85MM | Sinoma |

| 18 | Kevlar rope | Shanghai |

| 19 | Heating Element | Shanghai |

| 20 | Hydraulic valve | Taiwan |

| 21 | Drive gear box | FOSHAN |

| 22 | Heater wire | Nickel Material |

| No | Name | Spec | Unit | Qty |

| 1 | Belt wheel(lower) | 85MM | piece | 4 |

| 2 | Belt wheel(upper) | 85MM | piece | 4 |

| 3 | Gearing belt | 85MM | piece | 25 |

| 4 | Bearing | 85MM | piece | 4 |

| 5 | Air bag | 85MM | piece | 4 |

| 6 | Ceramic tube | 85MM | piece | 20 |

| 7 | Ceramic roller | 85MM | piece | 2 |

| 8 | Lower heating wire | 85MM | piece | 6 |

| 9 | Upper heating wire | 85MM | piece | 6 |

| 10 | Electromagnetic valve | 85MM | piece | 2 |

| 11 | Thermocouple | 85MM | piece | 5 |

| 12 | Thermocouple protection tube | 85MM | piece | 5 |

| 13 | Kevlar rope(fire resistant rope) | 85MM | roll | 1 |

| 14 | Rollers | 85MM | piece | 4 |

| 15 | Bearing | 85MM | set | 4 |

| 16 | Electromagnetic valve | 85MM | piece | 1 |

| 17 | Relay | 85MM | piece | 3 |

| 18 | Relay base | 85MM | piece | 3 |

| 19 | Terminal blocks | 85MM | piece | 3 |

| 20 | Fuse core | 85MM | piece | 5 |

| 21 | SSR | 85MM | piece | 10 |

| 22 | Press-button | 85MM | piece | 5 |

| 23 | Relay | 85MM | piece | 5 |

| 24 | Level | 85MM | piece | 1 |

Heaters in top of furnace

Heat pipes are arranged in a split way so that the glass can be heated evenly

In the bottom of the heating section, above the heating elements, there are radiation plates, which is corrugated shape, no deformation under high temperature.

Broken glass pieces will fall down on the radiation plates, easily and convenient for cleaning;

Ceramic bricks, customized, precisely diameter, small gap, durable, better insulation performance, easily replacement.

Ceramic roller size: 65MM diameter